Industry 4.0 - Smart factory at ArcelorMittal

At the Bremen plant of the world's largest steel producer ArcelorMittal, the networking of IT systems and production facilities, the self-organization of the systems and the integration of an advanced dispatching system recently increased production efficiency and flexibility.

The modern architecture of the resultant IT landscape protects the sustainability of the investment. OHB Digital Services provides support with advice on agile software development as well as development and integration.

Improvement of production scheduling with SASKIA

An essential step is the roll-out of the SASKIA production scheduling system. For a very long time, manually planned campaigns were the norm. Looking forward, production scheduling will be largely automated. This involves the use of algorithms which can utilize the systems even more efficiently. This is primarily achieved by combining the physical properties of the materials with production costs and system restrictions. The results are greater production flexibility and efficiency. Another advantage of the solution is that it creates a common view for dispatchers as well as for the control center in production. The transparency created in this way enables us to make the right decisions together at any time. A high degree of scalability makes it possible to continuously improve the system and expand it on a modular basis after successful use.

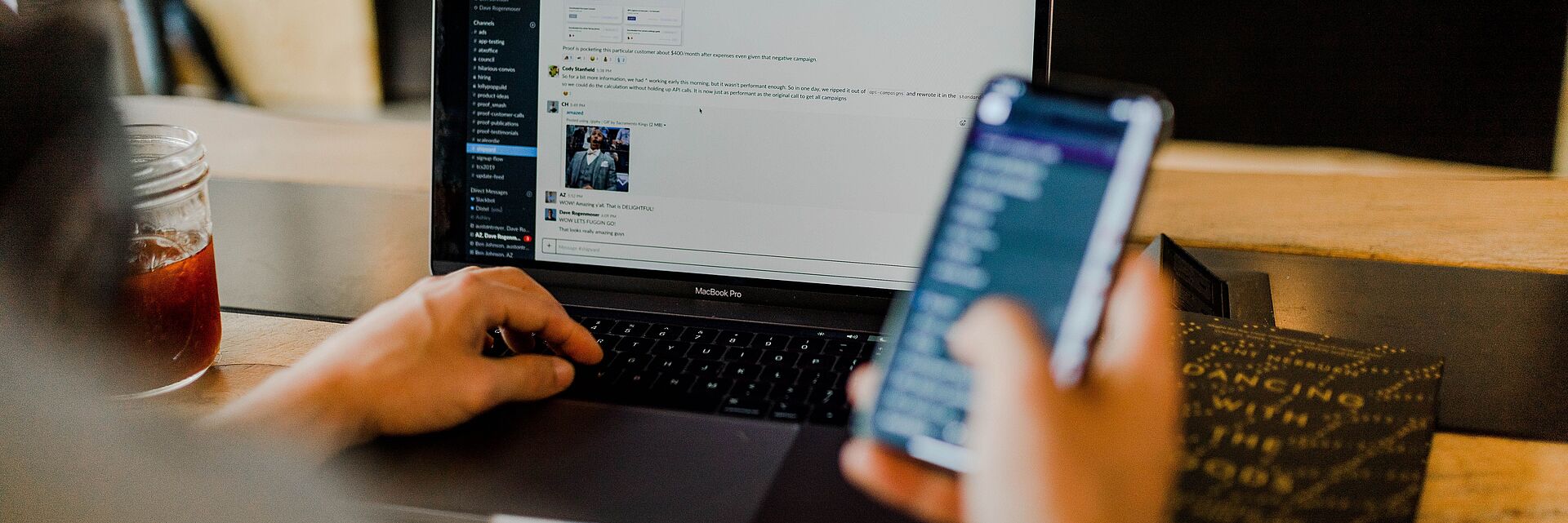

AMBus integration platform

The integration of production planning, the material database, scheduling system, production facilities and other systems is achieved by using an integration platform developed by ArcelorMittal Bremen, the AMBus (ArcelorMittal Bremen Bus). Thanks to the loose coupling of the systems via the AMBus, changes and extensions can be easily implemented. This outstanding scalability has been demonstrated several times through the step-by-step integration of an increasing number of IT systems and production facilities such as the packaging system for hot-rolled black coils.

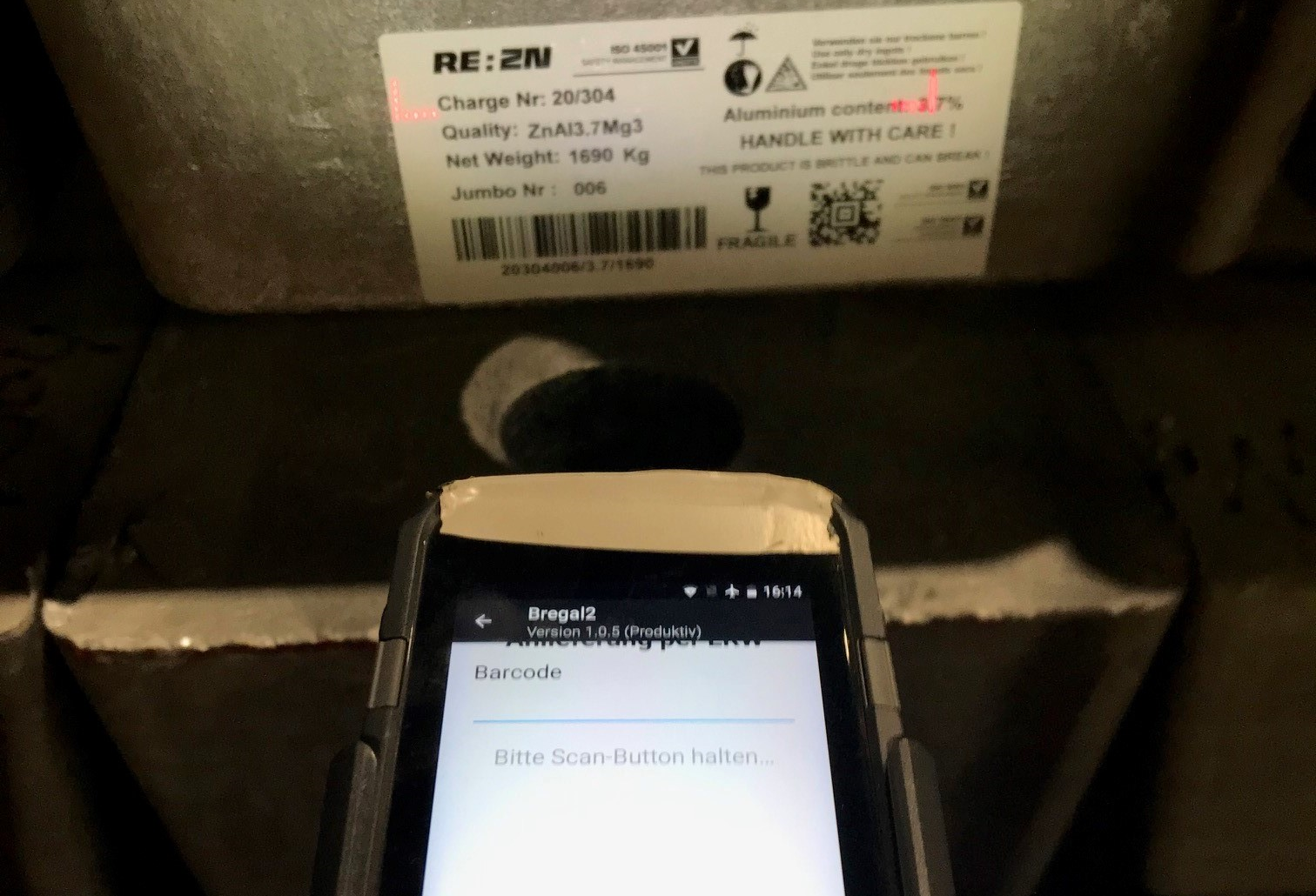

Packaging line for hot-rolled black coils

In the interests of more flexible production across the overall network of all systems, stand-alone processes must be consolidated. Currently, this can be viewed through the consolidation of the packaging of hot-rolled black coils in a specially developed new system. Looking forward, these warm coils will be strapped with thicker packaging tape as part of the HRC logistics project. This makes the entire packaging process safer and also reduces the previously high packaging costs of the coils.

Crane automation

The automation of warehouse management also plays a major role in Bremen. In particular, crane movements will be increasingly automated in the future. Process standardization across plant areas allows ArcelorMittal Bremen to use specially developed software, which initially replaces the existing systems and then permits the smarter use of automation tools.