Management system for zinc slabs (Zinkbrammen)

OHB Digital Services is developing a software solution for a more efficient registration and management process for zinc slabs for its long-standing partner, the world's largest steel group ArcelorMittal, which is located in Bremen.

Customer benefits

-

Time savings due to a simplified registration process for deleveries

-

Establishment of an innovative, holistic management system for zinc slabs

-

User-friendly system due to reduced input requirements and intuitive usability

-

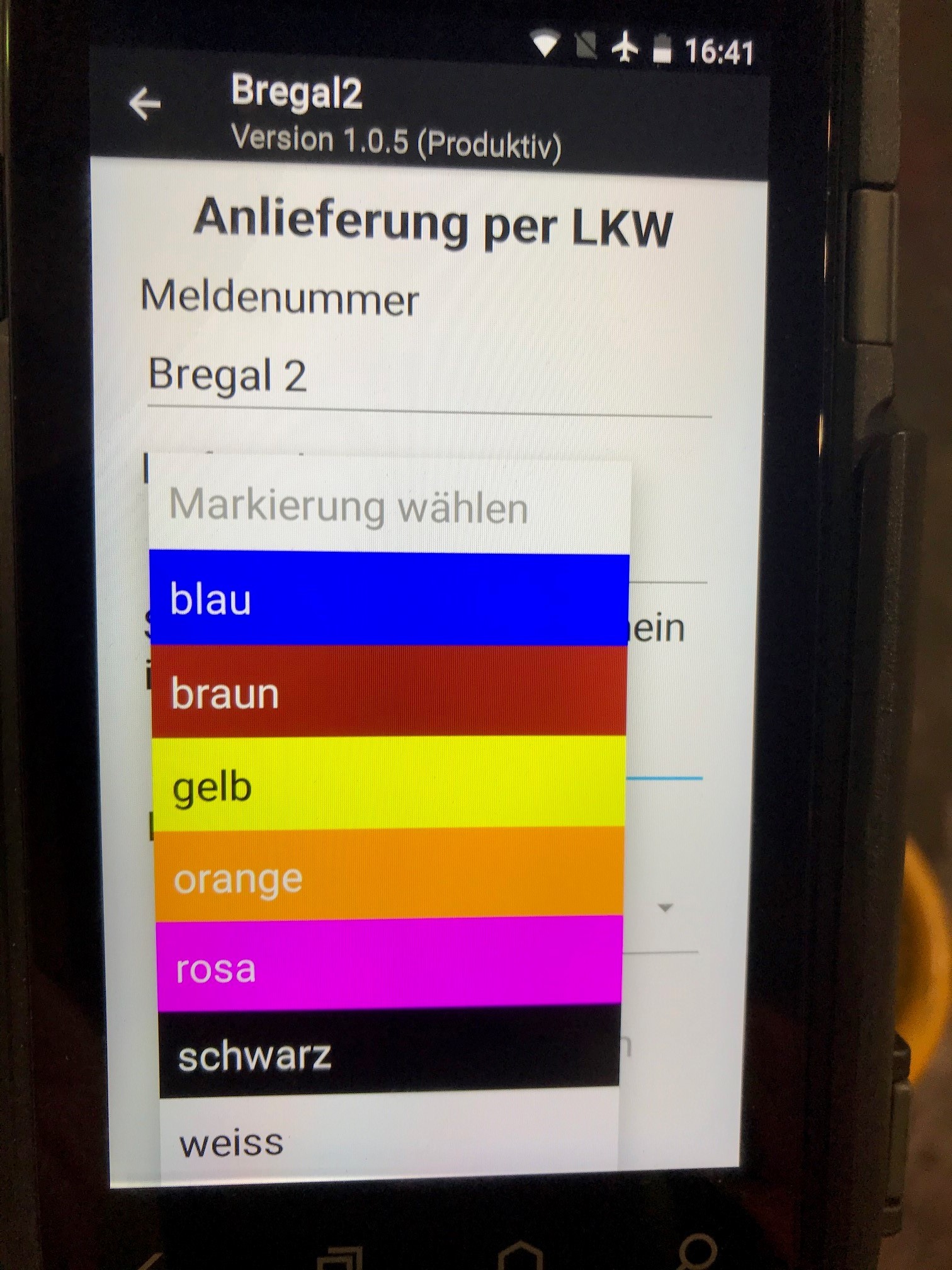

Process optimization by reducing the number of errors. Manual input of colour codes of the zinc slabs has been eleminated

Simple solutions - huge effect

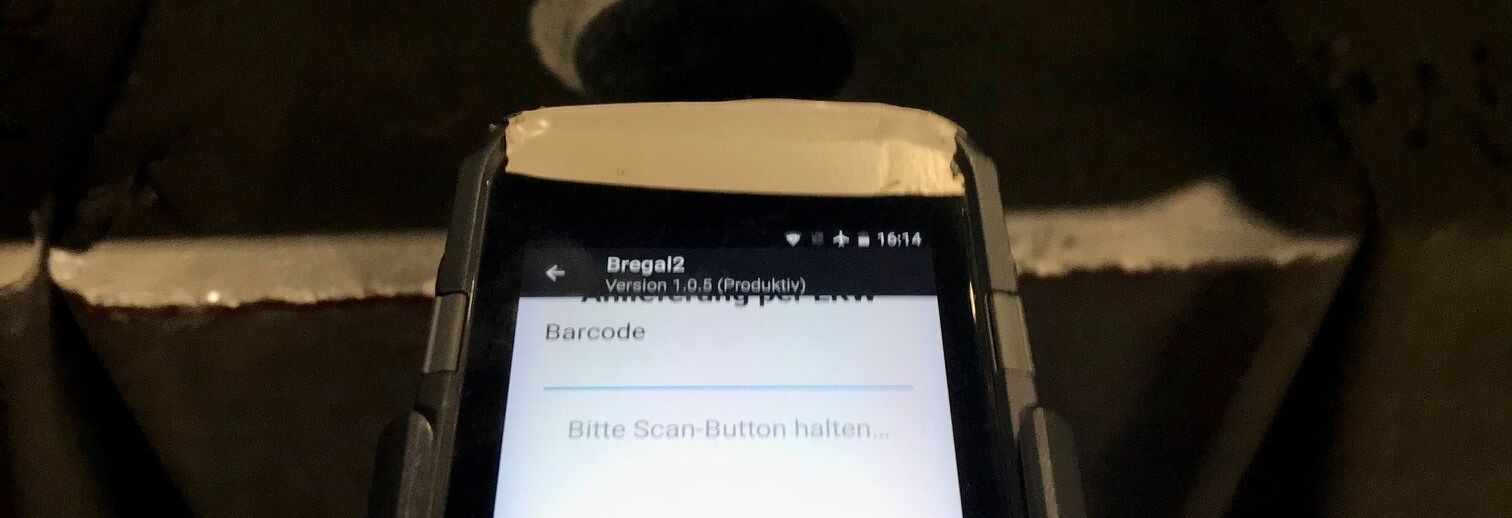

Instead of manually inputting every single zinc slab, it is now possible to register the entire delivery. A barcode scanner registers the colour codes of the zinc slabs in each delivery. Zinc slabs are marked with a colour code in accordance with international standards. This eliminates the need for the previous manual registration of every single zinc slab. The registration process is now about 10 times faster, yielding significant time savings. The inflow to galvanizing lines Bregal1 and Bregal2 is regulated on the basis of the color codes permitted for the respective galvanizing line. This small modification has had a huge effect. The registration process results in fewer errors and greater efficiency. In addition, the software permits the end-to-end management of zinc slabs, from delivery and warehousing to deployment and inspection as well as shipping and inventory management.

Individual consulting for custom-fit software solutions

The analysis of the operation processes during initial consultation idenfities the objective that needs to be revised and enhanced during the project. Unnecessary operations are eliminated to ensure that the project helps to simplify projects. This results in customized software that not only achieves the objectives of ArcelorMittal but also delights the end users.