With the combination of artificial intelligence, smart sensors and satellite data, we create a user-friendly, high-performing and customizable digital twin of business processes. Satellite data can help to efficiently digitize corporate processes.

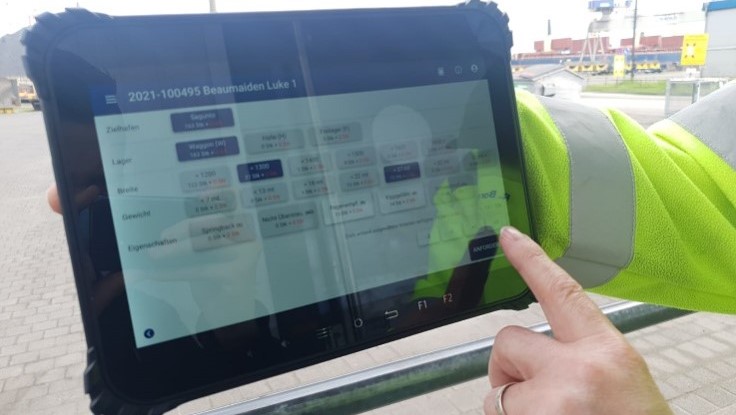

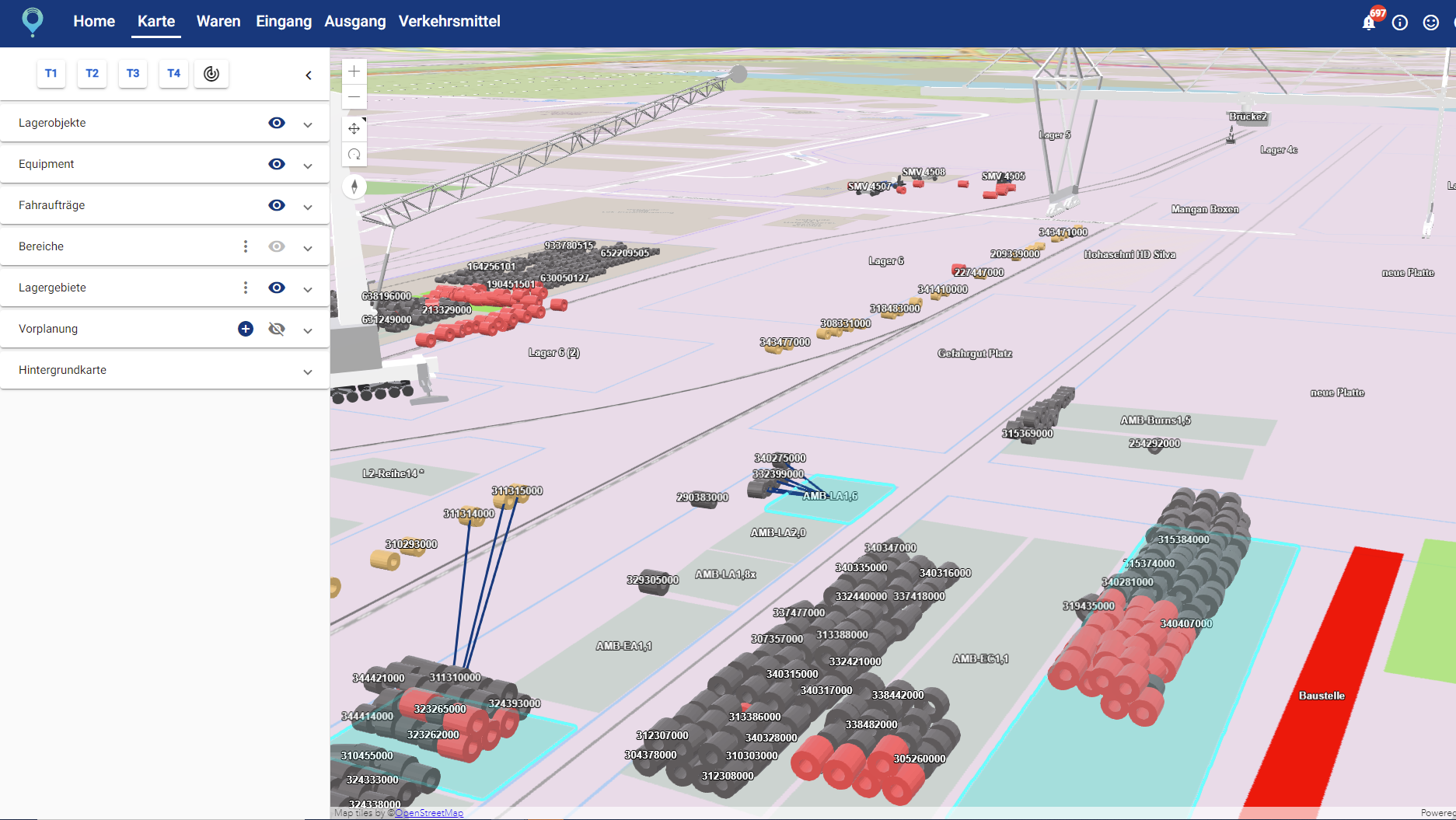

Labels of goods are often not very weather resistant and hardly scannable after some time. On top of this, it is very time-consuming scanning the goods before each movement. With OHB LogTwin, this is a thing of the past. The goods only have to be scanned once on receipt and assigned a position. Then the goods are stored in our fully digital ecosystem. Thanks to very precise vehicle location with a deviation of just a few millimeters, the goods are uniquely identified in the system with every movement and the position changes fully automatically during the transport. Every means of transport can be integrated: cranes, trucks, wagons, forklifts and way more. Storage areas can be flexibly created and dynamically modified in the system without a software developer, and periodic pre-planning makes planning warehouse scenarios way easier. A great deal of time ist saved. Moreover, comfort and safety are guaranteed.

Many logistics systems and warehouse management systems are very fragmented. Hardly any software can cover all use cases of a company. Several programs always have to be integrated. With OHB LogTwin, the customer's entire logistics chain can be tracked and applied to all types of goods. High-precision goods-tracking, a constant overview of the various types of goods and a permanent inventory help maintaining an overview of the warehouse, as well as optimizing goods movements and reordering goods in time. The system even recognizes transfers from indoor warehouses to outdoor warehouses and vice versa automatically and enables a seamless transition. The order picking is also illustrated on the map by the system. LogTwin is the one-stop shop solution for your intralogistics.

Handling companies of all kinds manage large numbers of different goods in very large quantities, in very extensive storage areas every day. Many of these goods are difficult to distinguish, resulting in long search times. The OHB LogTwin system enables that all goods are just few seconds away. Search times are a thing of the past and the integration in our forklift guidance system permits precise and automatic placement of transport orders for a considerable increase in efficiency in intralogistics.

Airports are areas with particularly strict safety regulations due to a high risk of accidents. Only a few people should be on the field at any time. Our fully digital twin helps to reduce the number of people on the field in connection with intralogistics and at the same time create more safety. This is done, for example, by automatically guiding vehicles along defined routes - and in the future autonomously as well. At the same time, the location of the goods are transparent at all times.Additionally, to further increase security, our security system identifies peoples on the airfield with help of camera data, GNSS-trackers and AI-models.

Need to manage transports of longer distances? No problem with LogTwin - whether on rails or on the road. Thanks to multiple redundant GNSS receivers on the vehicle, goods can be tracked in real-time anywhere in the world. The handover of the load to the customer is also greatly simplified by an automatic inventory of the load. Furthermore, the customer receives a dashboard to see the location of the goods at any time, as well as a constantly updated ETA with the inclusion of various environmental dates.

Construction sites, especially large ones, can quickly become very complex. Many different types of goods are parked on the site, resulting in the challenging task for the construction management of keeping an overview of the location of each good and to order the goods to their place of use in-time. This task is simplified with OHB LogTwin enormously. No goods can be lost any more and individual transport orders can be created at any time. Even several locations can be displayed in LogTwin at the same time. This is rounded off by a tidy and intuitive user interface.

Companies that want to avoid labels/barcodes/RFIDs & their misuse.

After incoming goods are entered, all position and movement bookings are executed without any additional necessary labels/entries in the closed LogTwin ecosystem. This prevents erroneous bookings and the location of the goods is always known.

Companies with (a need for) flexible warehouse space.

If different goods at different times form a large part of the total turnover, LogTwin offers the benefit of individual storage area planning, which can also be simulated for the future in order to "activate" it. At the same time, warehouse space is adaptable at any time with a simple click of the mouse, without any need for further software development.

- Flexible warehouse space, dynamic adjustment without software developers

- Periodic pre-planning support for warehouse scenarios

- Different locations can be mapped and controlled simultaneously in a single system

- AVIS/AIS/weather data as well as many other types of data can be integrated

- State-of-the-art architecture and UI, custom KPI dashboards